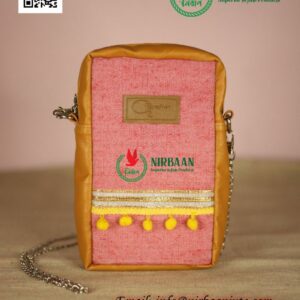

Jute Designed Bag

Jute is a type of natural fiber that is commonly used to make bags, baskets, and other similar products. Jute bags are often favored for their eco-friendliness, as jute is a renewable resource that is biodegradable and compostable.

Jute bags can be designed in a variety of styles, from simple and functional to stylish and decorative. Some jute bags are plain and solid colored, while others are printed with patterns or designs. Some jute bags feature additional materials, such as leather or cotton, to add extra strength or durability.

Jute bags are often used as shopping bags, grocery bags, and beach bags, due to their large size and sturdy construction. They are also popular as promotional items and are often customized with company logos or branding.

Overall, jute bags are a versatile and eco-friendly option for carrying goods, and their natural texture and durability make them a popular choice for many consumers.

The process of making a jute designed bag involves several steps, including:

- Sourcing the jute material: Jute fibers are obtained from the stem of the jute plant, which is grown in many countries around the world, such as Bangladesh, India, and China. The jute fibers are then cleaned, sorted, and processed into jute yarn.

- Designing the bag: The first step in designing a jute bag is to determine its size, shape, and overall style. This can be done using a paper or digital mockup, or by creating a sample bag using fabric or other materials. The design can also include any additional features, such as pockets, zippers, or straps.

- Cutting the jute fabric: Once the design has been finalized, the jute fabric is cut to the appropriate size and shape to create the pieces that will be used to make the bag.

- Sewing the pieces together: The pieces of jute fabric are then sewn together to form the body of the bag. This can be done by hand or using a sewing machine, and may involve adding reinforcements, such as binding or hemming, to the edges of the fabric.

- Adding handles: Once the body of the bag has been sewn, the handles or straps are added. This may involve sewing them directly onto the body of the bag, or attaching them using loops or other hardware.

- Printing the design: If the bag is to feature a printed design, this step involves printing the design onto the jute fabric using a heat transfer or screen printing process.

- Finishing and quality control: Finally, the bag is finished by adding any final touches, such as trim, labels, or hangtags, and then undergoes a quality control inspection to ensure that it meets the desired standards.

Overall, the process of making a jute-designed bag requires a combination of manual labor and machinery, as well as attention to detail and quality control. The end result is a durable and eco-friendly bag that is both functional and stylish.